Case Study & Whitepaper

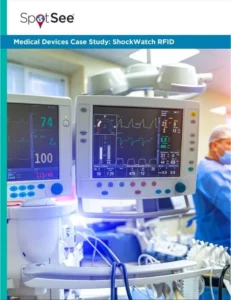

Medical Devices Case Study: ShockWatch RFID

Impact indicators have long been used to monitor medical equipment in transit. However, an RFID enabled impact indicator is just as valuable after medical devices are in service. The RFID will alert teams to possible damage due to impact as well as track equipment in use, lowering the loss of due to misplaced or stolen devices.

Freeze Indicator Case Study

Freezing isn’t good for many pharmaceutical products, so pharmacies, caregivers and, increasingly, patients, need a way to know whether their products froze in transit. SpotSee’s new freeze indicator provides that information.

Cabinetry Case Study: SpotBot Cellular

SenseIT IoT by Domain, combined with SpotBot Cellular, determines the impact level where damage may occur.

Flu Vaccine Cold Chain Case Study: WarmMark

SpotSee's WarmMark is an ideal solution for monitoring vaccine temperature during shipping and storage.

Saliva Indicators Case Study

For saliva diagnostic kits to be accurate they must have enough saliva to test.

Ship-to-Home Pharmaceuticals Case Study: WarmMark

In order to prevent harming a patient's health, and wasting time and money, pharmacies must monitor the proper temperature on medications during the shipping process to the customer.

Drug Test Temperature Case Study: BriteDot

To ensure that drug tests are accurate, drug testing facilities measure the temperature of the urine sample when provided.

Airline In-Flight Meals Case Study: Cook Check

An airline needs to ensure that food is reheated to a safe temperature before serving

Rail Car Bearings Case Study: Thermax

A major railway needed to monitor the working temperatures of rail car bearings.

Semiconductor Equipment Case Study – ShockWatch RFID

Semiconductor fabrication equipment and the silicon wafers they produce are extremely sensitive to impact.

Semiconductor Equipment Case Study – ShockWatch RFID

Semiconductor fabrication equipment and the silicon wafers they produce are extremely sensitive to impact.

Temperature Monitoring the COVID-19 Vaccine

Delivering COVID-19 vaccines to 7.8 billion people is a daunting challenge that will stretch supply chains past their limits.

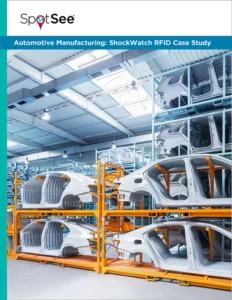

Automotive Manufacturing: ShockWatch RFID Case Study

A major automotive manufacturer was experiencing a high rate of internal supply chain damage to parts moving from plant to plant and within their warehouses.

Garage Door Manufacturing: ShockWatch RFID

A garage door manufacturer was dealing with a large number of costly returns because customers were receiving damaged doors.

Laboratory Equipment Manufacturing: ShockWatch RFID

A major laboratory equipment manufacturer was experiencing a high rate of internal supply chain

Offshore Drilling Case Study: SpotBot Cellular

Supply chain damage caused major operation waste and scheduling issues. See how they fixed it.

Steam Turbines Case Study: ShockLog Satellite

One steam turbine shipment can involve $10 million in fragile assets. See how this company is reducing costly transportation damage.

Airplane Auxiliary Power Unit Case Study: SpotBot Cellular

An international airline needed SpotBot Cellular to solve what was damaging the auxiliary power unit on their airplanes.

Automotive Instrument Panels and Bumpers Case Study: SpotBot Cellular

An automotive company used SpotBot Cellular to slow down their high rate of supply chain damage.

Wind Turbine Case Study: ShockLog 298

See how one company moved 80 wind turbines without installing a damaged one.

OpsWatch: Sand Silo

Using OpsWatch, this mining facility predicted sand silo failure 19 days before it occurred and avoided downtime.

Large Power Transformer Case Study: ShockLog 298

Large power transformers damaged during shipment? See how one company reduced incidents in their supply chain.

SpotSee David Edward Furniture: ShockWatch Label

David Edward has protected his high end furniture from supply chain damage for 25 years using ShockWatch Labels.

HJC protects customer orders & cuts freight claims: ShockWatch Label

After one year of using ShockWatch products and bolstering its packing and shipping procedures, HJC slashed freight claims from $300,000 down to

SOTA TOYS virtually eliminates breakage by packaging: ShockWatch labels

See how SOTA Toys was able prevent logistics damage and virtually eliminate a 50% reship and replace rate.

Understanding the Source of Product Damage

Where are my goods in the supply chain right now? How many goods are damaged in the supply chain? The number of questions we ask ourselves Think Centre

Choosing the Right Temperature Monitoring Solution

Cold chain solutions range from inexpensive indicators that alert shippers of mishandling to sophisticated monitors and data

Improving Quality Assurance in the Meat and Seafood Cold Chain

Meat and seafood must maintain exact temperatures throughout the cold chain. For these products, it’s not enough to ensure they are

Logistics Risk Management In The Transformer Industry

When shipping something big, expensive and hard to replace, it’s important to do it right the first time.

How to Prevent Logistics Damage to Electronics

Damage to electronics can’t usually be seen on the surface. Know if there’s damage where it counts.

Protecting Medical Devices in Transit

Impact, vibration and temperature will affect the usability of medical devices. Find out how you can monitor your tools during shipment, use and storage.

Marine Transportation for Pharmaceuticals

Did you know it costs 80%-90% less to ship cargo on a boat than through the air?

Logistics Network Analysis

Do you know where your shipping damage occurs and why? We can show you how to find out.

Protecting the Supply Chain from Temperature and Impact Damage

Stay calm, cool and collected knowing your shipment is calm, cool and collected.

Preventing Product Damage that Occurs During Shipment

Damaged products hurt your wallet and your brand. Keep unsalable product from being sold.

Developing a Risk Management Program

Data is only valuable if it is used. Use that information to reduce losses and improve the quality of your business.

Aviation and the Supply Chain

Shipping your product through the air is efficient but also presents its own set of challenges.

Assessing the Total Cost of Supply Chain Damage

SpotSee customers report in-transit monitoring has dropped damage rates by an average of 60%. Stop wasting time and money.