Ship-to-Home Pharmaceuticals Case Study: WarmMark

Summary: Shipping medications directly from a pharmacy to a patient’s home is a daily standard practice. Maintaining proper temperature during shipment is crucial. If temperature is not monitored and fluctuates, this can make the medication less effective and cause harm to a patient’s health. Adding a WarmMark® temperature indicator ensures the safety of customers, protects your reputation, and reduces time and costs.

Summary: Shipping medications directly from a pharmacy to a patient’s home is a daily standard practice. Maintaining proper temperature during shipment is crucial. If temperature is not monitored and fluctuates, this can make the medication less effective and cause harm to a patient’s health. Adding a WarmMark® temperature indicator ensures the safety of customers, protects your reputation, and reduces time and costs.

Product Solution: WarmMark Temperature Indicator Label

Ship-to-Home Pharmaceuticals Case Study: WarmMark

|

Company Profile Industry: Pharmaceutical Application: Direct-to-Consumer Shipping Challenge: Maintaining the proper temperatures during shipment |

|

Safeguard Direct-to-Consumer Pharmaceutical Shipments with WarmMark

Safeguard Direct-to-Consumer Pharmaceutical Shipments with WarmMark

Shipping medications from the pharmacy directly to patients at homes is standard practice today for the local drugstore as well as large regional and national chains. Maintaining proper temperatures during shipment, therefore, is a concern. That’s because fluctuations in temperature can shorten the usable life of some medications and make some others less effective or, sometimes, dangerous.

At the wrong temperature, some creams can separate, and lozenges can melt which can affect their potency (how well they work) which can be harmful to a patient’s health.

Insulin is a good example. It should be stored between 2°C and 8°C. At 25°C – a reasonable temperature to expect during warm weather – insulin’s shelf life drops to about six weeks. In that case, the insulin is still safe and effective, but a patient receiving a warm package may return it “just to be safe.” The result is added costs for the pharmacy and inconvenience for the customer.

Tablets and capsules often can be shipped and stored at room temperature or controlled room temperature. Much of the time, thermal packaging isn’t needed to keep these medications between the defined of 20°C and 25°C (68° 77°F), with excursions permitted up to 30°C (86°F), according to the United States Pharmacopeia. But if these solid medications become too hot for too long, they still may look the same. Therefore, it’s important to monitor pharmaceuticals to know, beyond a doubt, that they were handled safely.

Whether medications are shipped across town or across a region, adding a temperature indicator is a smart decision that can save pharmacies time and money in the long run.

2. Reduces returns, thus lowering your shipping and handling.

3. Shows attention to detail, thus protecting your reputation.

Validated thermal packaging is the first line of cold chain defence, but how do you know your packaging works every time and in all seasons? Unless you monitor product temperatures inside those packages, you don’t.

Adding a WarmMark temperature indicator to each pharmaceutical shipment is a small price to pay to avoid the much greater costs of failure.

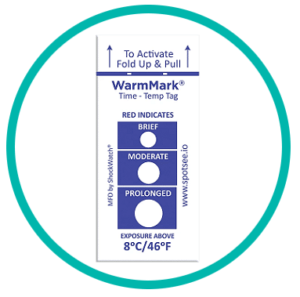

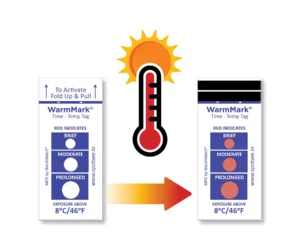

WarmMark is an easy-to-read thermal indicator that turns red when temperature excursions occur. Available in 10 temperature ranges, this temperature indicator features individual dots to signify brief, moderate, or prolonged temperature excursions. Importantly, those terms are defined, and vary based on the temperature threshold of the temperature monitor. For example, “brief” exposure means two hours at 0°C/32°F, but means 30 minutes at 25°C/77°F and above.

By adding WarmMark, a single-use temperature indicator, to packages, pharmacies can ensure their customers know the product they receive has maintained proper temperatures between the pharmacy and customers’ homes. If failures occur, their customers can see that, just by glancing at the indicator. Then they can contact the pharmacy or follow the brief instructions that you probably inserted along with the usage instructions. That way, they’ll know whether their medications should be replaced or whether they are still safe to use, and for how long.

Pharmacies also can use temperature monitoring to gain visibility into their

mail-to-home shipping program. Tracking any temperature excursions and correlating them with season, ambient temperature, packaging, carrier, or other parameters you can make adjustments that ultimately reduce your returns, thus reducing replacements costs (including the cost of medication and shipping).

The benefits of adding a temperature indicator to direct-to-consumer pharmaceutical shipments, far outweighs the costs. And, it protects you and your customer if temperature excursions do occur.

Contact us with any questions you have about this

case study or to schedule a meeting with a

SpotSee operations expert!

Safeguard Direct-to-Consumer Pharmaceutical Shipments with WarmMark

Safeguard Direct-to-Consumer Pharmaceutical Shipments with WarmMark