See How One Company Moved 80 Wind Turbines Without Installing A Damaged One.

Summary: The 400MW Trianel Windpark Borkum is the first fully large-scale municipal offshore project in Europe. See how they moved 80 wind turbines without installing a damaged one.

Product Solution: ShockLog 298

Wind Turbine Case Study: ShockLog 298

Industry: Power Generation

Application: Windfarm Logistics/Windfarm

Installation Challenge: The 400MW Trianel Windpark Borkum (TWB) is being built 250 miles/402 km offshore the Borkum island in the North Sea. Spread over 21 square miles, it is the first fully large-scale municipal offshore project in Europe; including 80 wind turbines. To prevent the costs associated with installation of a damaged turbine, TWB needed to understand what types of events would cause damage to their wind turbines and then monitor for those events.

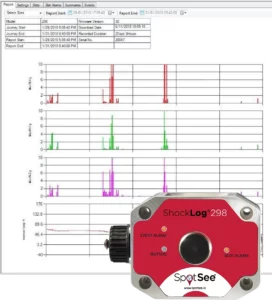

Solution: TWB selected the ShockLog 298 impact recorder for its ability to record direction, amplitude, and duration of impact forces. TWB determined that low frequency impacts (duration > 50 milliseconds) would be enough to cause a wind turbine to fail prematurely.

Once TWB knew what type of event would cause damage to their turbines, they purchased ShockLog 298s to monitor all 80 turbines for those events during transport, storage, and installation.

ShockLog® 298 Overview

Real-Time Impact Data

The ShockLog 298 is a highly durable impact recorder that can be configured to monitor critical parameters, providing an unmistakable alert that an impact to a shipment or equipment may have compromised its integrity, performance, or safe operation. The ShockLog 298 monitors impact, events, vibration, and internal temperature and provides peak value (time slot) and summary period journey profile data. Combined with either a cellular communication module (ShockLog Cellular) or Satellite communication (ShockLog Satellite), the ShockLog 298 can deliver information in real-time

Protect Your High Value Assets

Customers use the ShockLog 298 impact recorder to:

- Alert recipients and operators to inspect goods and equipment for potential damage

- Determine baseline damage boundaries

- Detect mishandling during shipping, operation, and storage, enabling you to identify and assign accountability and take corrective action

- Make adjustments to product packaging, loading process, carriers, or mode of transport

- Help identify opportunities for improvement through journey profiling

SpotSee Cloud

The SpotSee Cloud is where trip data is aggregated in real-time. Graphs are easy to read and include data such as specifics of impact with locations, impacts over time, impact histogram, and temperature.

SpotSee Cloud Features

- Access to your data from anywhere with a secure web portal

- Real-time reporting and tracking of incidents

- Alarms with location, time, impact g-level, direction of impact, and temperature

- Impacts-over-time visualization of each asset

- Histogram of the total impacts to an asset

- Temperature over time graph

Contact us with any questions you have about

this case study or to schedule a meeting

with a SpotSee operations expert!