Airline In-Flight Meals Case Study: Cook Check

Summary:Globally, airlines serve approximately one billion in-flight meals per year to their passengers in normal times. A major airline uses Cook Check to ensure that food is reheated to a safe temperature before serving to inactivate any bacteria that may have contaminated the meals.

Summary:Globally, airlines serve approximately one billion in-flight meals per year to their passengers in normal times. A major airline uses Cook Check to ensure that food is reheated to a safe temperature before serving to inactivate any bacteria that may have contaminated the meals.

Product Solution: Cook Check

Airline In-Flight Meals Case Study: Cook Check

|

Company Profile Industry: Airline Food Application: In-Flight Meals Challenge: Ensure that food is reheated to a safe temperature |

|

Cook Check Helps Airlines Serve In-Flight Meals Safely

Globally, airlines serve approximately one billion in-flight meals per year to their passengers in normal times. Quantas alone served 7.5 hot meals to passengers on its long-hauls flights, and Emirates served up to 180,000 per day before travel was curtailed during the pandemic. Now hot meals are being served on trans-oceanic flights and are making a comeback on longer domestic flights, as well.

From kitchen to galley, food safety is paramount. The single most important step large food service operations can take is to ensure that food is prepared properly and reheated to safe temperature before serving to inactivate any bacteria that may have contaminated the meals. Doing that requires testing meal temperatures at the point of serving.

Some 12 to 72 hours before meals are served, in-flight meals are prepared in commercial kitchens and blast-chilled to about 5°C. They are readied for delivery to the plane approximately four hours before departure time and, typically, are on-board one hour before boarding begins. Then, during the flight, they are reheated in on-board ovens and served to passengers.

Multiple, highly-detailed regulations throughout the world govern the safe handling of food. The Hazard Analysis and Critical Control Points (HACCP) framework, used in the U.S., EU, and UK, is an example. HACCP helps food services assess their operation’s food handling processes. It entails record-keeping that details safe reheating practices, as well as other food safety requirements. This guidance for Northern Ireland is an example. The UK’s version of HACCP devotes sections to catering and reheating, and specifies safe time and temperature combinations. The U.S. version includes a section specifically for seafood.

The versions of HACCP all acknowledge the same few precepts: the importance of proper sanitation and proper temperature control. When food is reheated, its temperature is not just a factor in palatability but is an important indicator of safety.

Although the initial heating performed at the large commercial kitchens that prepare the meals kills the bacteria, food-service operations that reheat food also must ensure the meals are reheated to a temperature that kills any bacteria that may have contaminated the food after it was initially prepared. Such bacteria may come from improper handling, including cross-contamination from utensils or environmental sources.

“When food is reheated, its temperature is not just a factor in palatability but is an important indicator of safety.”

This concern for food safety exists for airlines as well as any large food-service operation in which where meals are

prepared offsite and reheated. Schools, hospitals, and long-term care facilities, including assisted living homes and

correctional institutions, all must ensure that the food that is prepared in commercial kitchens, frozen, and delivered

to them for reheating at mealtimes is safe to consume.

Clostridium perfringens (C. perfringens), Salmonella, Staphylococcus aureus (Staph), Listeria, and Escherichia coli

(E. coli) bacteria are among the greatest threats to the safety of precooked, reheated food, according to the U.S.

Centers for Disease Control and Prevention. These bacteria thrive in moist, protein-rich environments and can

grow very quickly, with some doubling every 20 minutes. When ingested, they can cause illness, including diarrhea,

stomach cramps, fever and other symptoms. Sometimes, hospitalization is required.

Their threat can be managed by safely reheating cooked foods to an internal temperature of at least 165°F/75°C,

according to the U.S. Department of Agriculture. But, in a fast-paced service environment like an airplane or school,

how can you know that each meal reaches the minimum temperature to ensure its safety?

“These bacteria thrive in moist, protein-rich environments and can grow very quickly, with some doubling every 20 minutes.”

Several international airlines use SpotSee®’s Cook Check® temperature probes to ascertain the internal temperature of the food it is reheating.

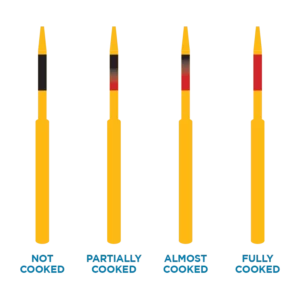

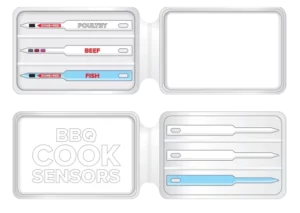

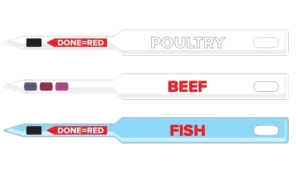

Cook Check temperature probes are made of food-grade polycarbonate and show that food has reached the proper internal temperature when the indicator dot on the probe changes color from black to red. The probes are irreversible, for singe use, to minimize the risk of cross-contamination.

To use Cook Check, flight attendants select a few meals per galley, per flight, to test. After the meals are reheated, they push the probe into the thickest part of the meat. After 10 seconds, they remove the probe and check the indicator. If the dot is red, the meat has reached the minimum safe temperature and can be served. If the dot remains black, galley crews heat the meals a bit longer and tests them again.

SpotSee’s food-grade polycarbonate probes can be inserted easily into meats – including steak and chicken. As a result, knives are unnecessary (a benefit, given modern flight regulations), and there’s no wastage because Cook Check temperature probes don’t crumple like some other probes.

These single-use temperature probes are accurate and can be used with all conventional cooking methods, including convection ovens, microwaves, and barbeques. They offer one important way to ensure that commercial food services deliver food from their kitchens, to in-flight galleys and, ultimately, to passengers, that is not only appetizing, but safe to eat.

Contact us with any questions you have about this

case study or to schedule a meeting with a

SpotSee operations expert!