Supply Chain Performance Metrics

There’s a wide variety of metrics available when assessing supply chain performance metrics and each will provide a slightly different perspective of the piece of the supply chain it measures.

There’s a wide variety of metrics available when assessing supply chain performance metrics and each will provide a slightly different perspective of the piece of the supply chain it measures.

For any company, an accurate overview of performance is essential. Performance metrics gauge growth, peaks, dips and unusual activity. The objective is to present a true indication of a company’s successes and failures, and areas that may be improved upon.

How A Performance Metric Works

When selecting the type of performance metric to use, a company should examine a number of different characteristics that align with their business.

When selecting the type of performance metric to use, a company should examine a number of different characteristics that align with their business.

User Friendly: It pays to use a performance metric that is easy to understand and presents clear, concise information. It should show what it is measuring and how the data is derived.

Quantitative Information: One of the most important features of a metric is that it is expressed by an objective value. This simply means that its information is derived from real data, not subjective data.

- Measures What Matters: The relevance of the data being measured is crucial to an accurate overview. A performance metric should only show information that is useful for business decisions to be made upon.

- Improves Behavior: Performance metrics should give indications of areas which need improvement, and provide some motivation to take action. An example is a metric that shows how many orders have been processed per day. A company can use this to implement a means of increasing the number of orders processed. In other cases, a metric may indicate the need to take action in some areas over others, such as increasing the number of movements at the detriment of containers loaded. This will then increase the number of orders processed.

- Easy to Collate: Time-consuming and complicated metrics are counterproductive, especially if staff are required to take time away from other activities to compile them. Useful performance metrics are those which provide information clearly and efficiently, without the need for extra time and attention.

Types of Performance Metrics

Three are three main types of supply chain performance metrics:

Time

Metrics that relate to time are those which are easy to understand and calculate. They should also provide a clear picture of how effectively the operation is performing. Examples include metrics that show the number of on-time deliveries and receipts, as well the time taken to process purchase orders and fulfill an order.

Cost

Cost is a major part of any business. Supply chain performance metrics showing cost efficiency can be the difference between a business’ success and failure. Profit is the aim for any company, and cost metrics help  to identify where money is being lost or gained. Inventory carrying costs is a particularly important metric as it shows how much money is being spent in carrying goods to a warehouse. The overall objective is to gauge where changes can be made to improve cash flow and make the business more profitable.

to identify where money is being lost or gained. Inventory carrying costs is a particularly important metric as it shows how much money is being spent in carrying goods to a warehouse. The overall objective is to gauge where changes can be made to improve cash flow and make the business more profitable.

Quality

Customer satisfaction should be a priority for supply chain-based businesses, and performance metrics must focus on improving quality at all times. This can entail metrics around customer service (including delivery times) as well as the quality of the product itself.

Other important performance metrics include:

- Order Measurement: Ensuring that the majority of orders are error-free

- Cash to Cash Cycle Time: How long it takes to deliver an order after the customer makes a purchase.

- Supply Chain Cycle Time: The time taken to fulfill an order if the item is unavailable.

- Cost of goods sold: A measure of the inventory turnover against profit.

- On Time Shipping Rate: The number of items or order values that arrive by the requested shipping date.

- Inventory Turnover Ratio: The number of times the company sells or turns over the average inventory. This is calculated by dividing Cost of Goods (COGs) sold by the average inventory investment.

- Days of Supply: Measures efficiency in the supply chain by dividing the average inventory on site by the average monthly demand.

- Next Month’s Sales Forecast: An estimation of pending sales.

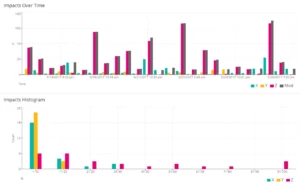

SpotBot Impact Monitoring and Tracking System

Using the SpotSee web-based platform, the SpotBot Impact Monitoring and Tracking System provides real-time data quickly and efficiently. It’s designed to deliver three-way impact monitoring and tracking which then can be accessed in the cloud from a computer or smartphone. Visit our blog to learn more about the ways our products can optimize your business shipping needs!