SpotSee Enables Predictive Maintenance in Mining, Oil and Gas Industries

One of the biggest frustrations of running a successful mining, fracking, or oil and gas/petrochemical operation is sudden or unexpected equipment failure. Sudden failure can result in expensive downtime, which leads to excessive costs and unavoidable delivery delays when preparing products for your customers.

Luckily, predictive maintenance via condition monitors can help such operations run smoothly by detecting potential problems before they occur. Equipment monitoring saves businesses money over the long term as it allows them to fix equipment before it fails — enabling longevity; avoiding costly, in-depth fixes; and keeping downtime (when you’re not making any money) to a minimum. It even gives you the insight necessary to plan maintenance during off-hours, rather than holding up production.

Want to improve the reliability of your mining or petrochemical (oil and gas) equipment?

Let’s take a look at options for monitoring equipment, what is required, and how proper monitoring can help you streamline your operations.

How Businesses Use Real-Time Monitoring to Prevent Downtime

Many businesses including mining, oil and gas, and fracking use vibration monitors.. Here are some examples of real-time monitoring.

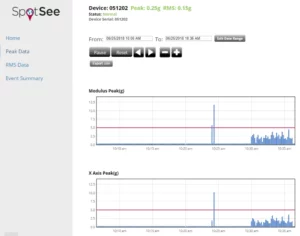

SpotSee’s OpsWatch monitors low-level vibrations and impact while equipment is operating. A frac sand transport facility in Texas implemented OpsWatch to monitor vibration data from their equipment. The information from OpsWatch’s vibration sensors allowed the facility to predict several events that preceded failure. In one instance, OpsWatch detected an unexpected spike in vibrations followed by some chatter. The operator stopped the elevator and discovered that it was in need of service.

SpotSee’s OpsWatch monitors low-level vibrations and impact while equipment is operating. A frac sand transport facility in Texas implemented OpsWatch to monitor vibration data from their equipment. The information from OpsWatch’s vibration sensors allowed the facility to predict several events that preceded failure. In one instance, OpsWatch detected an unexpected spike in vibrations followed by some chatter. The operator stopped the elevator and discovered that it was in need of service.

In another instance, wet sand caused a weight increase, which resulted in the elevator system getting backed up. The OpsWatch condition monitor recorded vibrations that exceeded the normal threshold and operators were able to fix the problem before it became critical.

OpsWatch can also monitor the vibrations in high-pressure pumps and valves used for fracking. Fracking valves can experience pressure levels up to 10,000 psi, which can cause the valves the wear and fail quickly. Vibration analysis of the levels of these valves allows companies to detect problems before a failure occurs.

OpsWatch can also monitor the vibrations in high-pressure pumps and valves used for fracking. Fracking valves can experience pressure levels up to 10,000 psi, which can cause the valves the wear and fail quickly. Vibration analysis of the levels of these valves allows companies to detect problems before a failure occurs.

In both cases, SpotSee’s OpsWatch vibration monitor stepped in before damage occurred to alert maintenance staff of impending issues. Without OpsWatch in place, these companies would not have known their machinery was in danger until it had actually broken down — costing them thousands in lost productivity, not to mention collateral damage. Predictive maintenance, identified via OpsWatch, allowed machine maintenance to happen conveniently and preventatively, instead of intrusively and reactively.

Important Features for Predictive Maintenance Monitoring

So what features should you look for when implementing an equipment monitoring system?

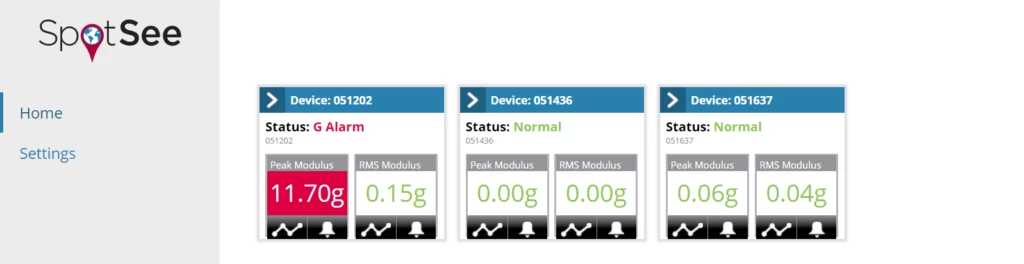

Accurate condition and vibration monitoring with instant alerts is perhaps the most important feature. Instant alerts allow operators to detect problems quickly and take immediate action.

The ability to monitor conditions remotely and conduct vibration analysis is also desirable as it will allow supervisors and others not in the immediate area to get notified. Maintenance or operations staff at the headquarters can analyze data and alerts and deploy staff already on site to address the issue.

Having a wide breadth and depth of data is another desirable feature that will allow businesses to analyze their operations over the long term. Such data is useful for spotting recurring issues and trends that may need to be addressed to keep operations running smoothly.

Ultimately, the goal of equipment monitoring is to protect critical pieces of equipment and avoid costly downtime.

Preventive Maintenance vs. Predictive Maintenance

Detecting problems with proactive monitoring and predictive maintenance will help improve productivity and reduce downtimes, but operators should still do regular preventive maintenance. What is preventive maintenance? Preventive maintenance is regularly scheduled maintenance. What is predictive maintenance? Predictive maintenance is scheduled based on equipment conditions.

Systems like OpsWatch gather data so that you can make better decisions on when and how to schedule preventive maintenance. OpsWatch also sends alerts when conditions deteriorate so that maintenance personnel can schedule predictive maintenance. If OpsWatch vibration sensors identify recurring operational issues, maintenance staff can analyze those trends and build better preventive maintenance schedules.

Regular preventive maintenance, active equipment monitoring, and identifying opportunities for predictive maintenance will allow you to minimize the risk of costly and unexpected downtime from equipment failure.

Handheld vs. Automated Monitoring Devices

One solution that operators can employ to detect equipment problems are handheld monitoring devices. These devices are easy to use and an operator can use them to periodically measure equipment vibrations, temperature, and other important data. But often, the downsides outweigh the benefits. Despite their availability and ease of use, engaging handheld devices takes more time than using an automated system and can actually end up being more expensive.

Automated monitoring systems, such as OpsWatch, allow you to monitor equipment and devices continuously in real time. Real-time monitoring is important because equipment failure sometimes happens quickly, without prolonged out-of-threshold measurements acting as an advance warning. And in many cases, early detection of potential problems can allow technicians to fix the equipment before it becomes too costly.

Automated Monitors Are Simple to Set Up and Utilize

To start off, you will need to measure the vibration levels of your equipment in standard operating conditions to get a baseline for the vibration range that the equipment should operate in when things are running smoothly. Once you have established a normal range, your monitoring device should alert you whenever vibration levels exceed the normal thresholds.

The equipment operator should then investigate the issue and fix the problem. Investigating may require temporarily halting operations, but fixing the problem now can prevent more costly problems, like equipment failure, later on.

Learn More About How OpsWatch Can Help Your Business

OpsWatch is a cost-effective solution that you can easily configure to deliver equipment and condition data through a web-based platform using Wi-Fi connectivity. It allows you to monitor vibrations and receive alerts in real time when conditions exceed set limits.

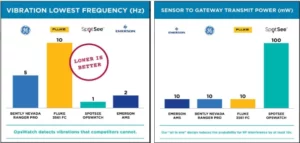

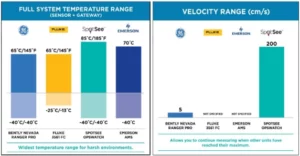

Of course, OpsWatch isn’t the only vibration monitoring solution, but it boasts capabilities high above the competition to make it the ideal choice. Its battery-free design (it’s powered directly from the machine it’s mounted on) means 10 times more transmission power that competitors for better link reliability and a much higher volume of data. OpsWatch also features the lowest floor for vibration frequency detection — important, since low-frequency vibrations have a higher potential to be damaging — so it can monitor a more expansive selection of machinery, including slowly rotating equipment. Plus, an acceptable operating temperature range from -40-85℃, the largest on the market, means OpsWatch performs flawlessly even in harsh environments. The velocity range is wider, too, providing measurements as small as 7mm/s and as large as 2,000mm/s throughout a range of 1-200cm/s.

Want to learn more about how SpotSee’s OpsWatch can help your operations? Check out our product page or download the OpsWatch Overview PDF to learn more about the competitive advantages that OpsWatch provides. And reach out to a SpotSee professional via the contact form below if you need help identifying the right solution for your business.