RFID Tracking Labels are the Future of Packaging

The future of packaging involves RFID tracking stickers. You’ve probably heard that before, but today’s passive RFID tags have won the respect of business leaders who are doing more than just slapping a tag on a crate and calling it done.

Passive RFID tags are being deployed everywhere, from jackets at Macy’s to rail cars throughout the world, as companies realize that inventory tracking is critical, and that RFID tracking stickers are a viable solution to gain visibility into their supply chains.

Not too long ago, IoT devices made alerts possible in real and near-real time. Then analytics software adapted and caught up, so real-time insights were possible. Now, knowing where items are and knowing their condition has become a real competitive advantage.

RFID Shipping Solutions Start with Packaging

With modern, mature technologies available and affordable, 90 percent of companies are rethinking their packaging, according to a DHL survey. Adapting packaging to smart technologies was, in fact, one the respondents’ top three priorities. FedEx has already ingrained RFID tags into their supply chain and plans for mass rollout.

Smart tags, like SpotSee’s ShockWatch® RFID indicators communicate with you throughout their supply chain journey, all the way to their installation. They have the potential to reduce damage, diversion, and counterfeiting, and make a noticeable contribution to the bottom line. Implementation of a ShockWatch monitoring program can reduce shipping damage by 40 – 60%. And these indicators stick right onto the crate, instantly creating RFID-connected packaging.

Smart tags, like SpotSee’s ShockWatch® RFID indicators communicate with you throughout their supply chain journey, all the way to their installation. They have the potential to reduce damage, diversion, and counterfeiting, and make a noticeable contribution to the bottom line. Implementation of a ShockWatch monitoring program can reduce shipping damage by 40 – 60%. And these indicators stick right onto the crate, instantly creating RFID-connected packaging.

SpotSee’s ShockWatch RFID tags provide two levels of insight. Most obviously, they confirm that a package – or hundreds of packages on a pallet – reached a given point. Passive tags mean that items are scanned automatically, without human intervention, whenever they pass an RFID scanner. Some operations have scanners at the loading docks. Others use drones for continual updates inside distribution centers and warehouses.

SpotSee’s RFID tags also report on the condition of the items. Specifically, they monitor impacts. With sensitivities ranging from 5G to 75G, these indicators help you detect mishandling and hidden damage. Not only do they turn red for visible confirmation, they automatically report the fact that a potentially damaging impact has occurred when scanned by the UHF RFID reader. Therefore, a technician about to install a part can check the tag, see that it may have been damaged, and set it aside. An engineer can see that the turbine that was shipped halfway around the world arrived with no incidents, or that it needs further inspection before it’s put into operation.

Knowing about potential damage up front can mean the difference between installing a damaged transformer on the plains of Montana or Kenya versus diverting it to a convenient city for repair mid-shipment. It can mean finally understanding why a new computer failed, or what changes you can make to packaging materials or shipping procedures to reduce warranty repairs and traffic in your own reverse logistics program.

RFID Tracking Stickers Enable Massive Logistics Optimizations

Tracking is only one aspect of supply chain optimization, of course. The bigger picture is how to use the information RFID tracking stickers provide to generate a robust return on investment.

One strategy is to use RFID tracking stickers to minimize the risk of counterfeit or diverted goods. With RFID tracking, it’s evident if a shipment misses a checkpoint. Because the tags are serialized, its easy for you to match the serial number on the package to the one reported on the bill of lading. If they differ, the tag has been replaced in transit and you should check the contents carefully to ensure they haven’t been diluted with counterfeit goods.

Another approach is to increase the tags’ visibility to decrease damage. Studies, starting in the early 20th century, and anecdotal reports show when people know they are being watched, they behave differently. In the logistics industry, that means they are more careful. So, when cargo is marked in a way that clearly indicates it is being monitored, damage generally decreases.

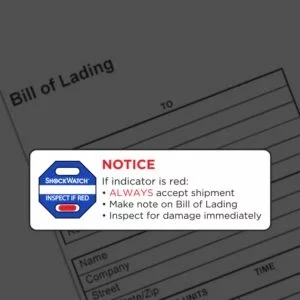

Marking cargo doesn’t mean sticking a “fragile” label on a carton. (That may actually have the opposite effect!) Instead, use a SpotSee Companion Label. It sticks to the carton and the passive RFID tag sticks to it. It’s easy for handlers to see and contains information on what to do if the tag turns red (indicating a threshold impact event).

Likewise, the SpotSee Alert Sticker sticks to the bill of lading and alerts the carrier and consignee that this shipment is being monitored. It, too, has instructions in case the tag turns red. These accessories help minimize damage by alerting carriers that this shipment is monitored with RFID shipping solutions.

Likewise, the SpotSee Alert Sticker sticks to the bill of lading and alerts the carrier and consignee that this shipment is being monitored. It, too, has instructions in case the tag turns red. These accessories help minimize damage by alerting carriers that this shipment is monitored with RFID shipping solutions.

Proactive logistics management is an integral part of the supply chain today and will only become more important going forward. Communicative technology like UHF RFID tags and monitoring solutions that are enabled by WiFi, cellular, Bluetooth and other technologies not only let you know whom to hold accountable for damage, but provide the hard data you need to make decisions about packaging, carriers, and lanes so you can prevent future damage.

Packaging is getting smarter. RFID tracking stickers are an important, smart packaging technology that helps you stay ahead of the packaging and logistics curve.

Learn more about SchockWatch RFID and its uses in supply chain technology.