Aerospace Supply Chain Monitoring

Condition Monitoring for Aerospace Logistics

Components throughout the aerospace supply chain are durable enough to withstand runway landings and rocket launches, but the trip from individual vendors to the final assembly location may be another matter. Before they are assembled, many lack the robust impact protections they will have inside the aircraft or rocket. Therefore, they are susceptible to damage from unexpected impacts.

The aeronautics and aerospace supply chains are truly global, with suppliers of major components located throughout the world. The Airbus A380, for example, is made from approximately 4 million parts produced by 1,500 companies in 30 countries. Problems in logistics, therefore, can set back production, delaying deliveries and affecting customer services as well as the manufacturer’s finances.

Aerospace Supply Chain Optimization

Condition-handling monitors are a vital part of a supply chain risk management program. They can alert manufacturers to parts that have experienced rough handling early before they enter inventory, so they can be thoroughly inspected.

There are several cost-effective monitoring options ideal for aerospace logistics:

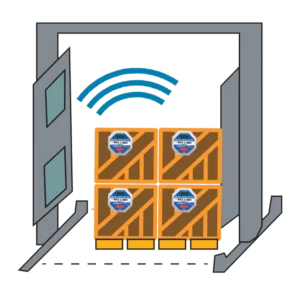

ShockWatch RFID tags are available with impact thresholds that range from 5 and 75Gs and feature passive RFID-enabled sensors. Therefore, each time the tag passes an RFID scanner, its condition will be logged and automatically added to the inventory management system or enterprise resource planning software. The tag also turns red, providing a visual indicator that the cargo may be damaged.

|

ShockWatch RFID will “activate”

![]()

SpotBot Cellular is a shock recorder that provides real-time shock monitoring intelligence so managers can inspect or divert shipments for repairs. Data is delivered to the SpotSee Cloud using SpotSee Connectivity, SpotSee’s own low-cost mobile virtual network that provides global coverage anywhere there is cellular reception.

ShockLog Satellite monitors impact and reports in real-time via satellite on peak events, so you know exactly when and where threshold excursions occurred.

g-View is a shock recorder that monitors impacts on the X, Y, and Z axes, recording the date, time, internal temperature, threshold exceeded, and amplitude for each axis. It’s ideal for when real-time reporting isn’t needed. Instead, g-View provides a downloadable impact report and lights up so those threshold alarm lights alert those receiving the cargo know to check it for damage.

Mitigate the Risks of Sensitivity and Fragility in Aerospace Logistics

Of the many components that make up an airliner, the airframe is the largest. Built in sections, airframe components for AirBus, for example, travel by road, river and sea ferry before reaching their final assembly point. A loose tie-down on a truck bed or rail car can allow the fuselage to roll, potentially causing damage. Likewise, an impact with a dock can stress the components, causing the potential for failure later on. Transferring large components, like fuselage sections, among modes of transportation and positioning them in place at the manufacturing facility also can be risky.

There are countless smaller parts in the aerospace supply chain that may be damaged in transit or storage, too. For example, the Nomex™ honeycomb and aluminum honeycomb used for frames in rockets, jet engines, and propellers is fragile by itself. It may be crushed during in-transit impacts. Interior cabin sidewalls may be cracked. Circuit boards, overhead lights and electronics for the cockpit and main cabin are susceptible to small impacts that may fracture delicate connections.

There are countless smaller parts in the aerospace supply chain that may be damaged in transit or storage, too. For example, the Nomex™ honeycomb and aluminum honeycomb used for frames in rockets, jet engines, and propellers is fragile by itself. It may be crushed during in-transit impacts. Interior cabin sidewalls may be cracked. Circuit boards, overhead lights and electronics for the cockpit and main cabin are susceptible to small impacts that may fracture delicate connections.

The list of components that may be damaged is long, and it’s exacerbated by the increasing fragility to advanced materials. The makers of passenger and cargo planes, Saturn rockets, and SpaceX capsules all aim towards greater fuel efficiency and capacity. Consequently, they look for components that are lighter and stronger than their earlier counterparts. In electronics, this often means thinner connectors, and in materials, tighter tolerances. All this increases the potential for in-transit damage.

With the possible consequences of unseen damage high, failure is not an option. It is vital to identify components that may have been damaged before they are installed when malfunctions and accidents can be prevented. Aerospace supply chain optimization is imperative.

Aerospace manufacturers are deploying real-time information-sharing platforms throughout their manufacturing and supply chain operations to reduce risks and ensure critical parts supplies are uninterrupted. Condition monitoring is one such platform.

To learn how condition monitoring can help you reduce your risks and streamline your aerospace supply chain and operations, chat with us.

Case Studies

Read the Case Study

Read the Case Study

Product Recommendations

|

|

|

|

|

|

ShockLog Satellite

ShockLog Satellite